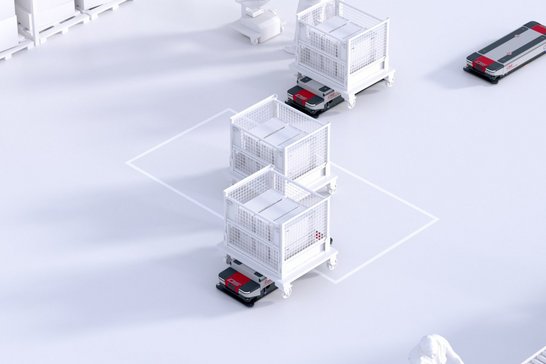

FLEXIMOVER Spin

The compact mounting solution for station linking in confined spaces

- Turns on the stand

- two directions of travel

- 360° all-round protection

Safety in the process

With its robust design and high positioning accuracy, the Fleximover Spin ensures maximum availability in the plants. Not only after final acceptance, but also many years later. The standardized PLC components, on which the in-house developed vehicle software runs, also ensure the long-term availability of spare parts.

Compact design

Thanks to its low overall height and recessed base, ergonomic working is possible from all sides. Accessibility to all vehicle components is always ensured in order to make maintenance and repair work as convenient as possible during operation.

Freedom in plant design

Thanks to the proven differential drive, there are hardly any limits to the system design. Moving the smallest radii up to turning at a standstill are no problem with the FLEXIMOVER spin. Automatic stations can be driven both forwards and backwards, ensuring full flexibility in process planning.

Experience more highlights

The perfect vehicle for your requirements

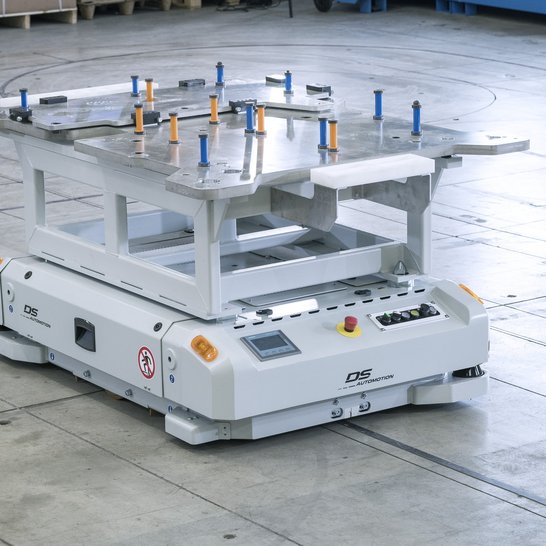

Pre-assembly

Every production process has specific requirements in terms of work steps, flexibility and ergonomics. The integration of automated guided vehicles in pre-assembly allows processes to be optimized and automated down to the smallest detail and manual operations to be efficiently combined. We have already implemented more than 100 systems in the field of pre-assembly and can respond to your requirements in a very targeted manner thanks to our extensive expertise.

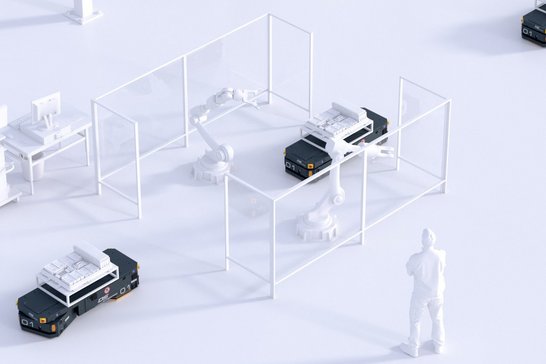

Final assembly

Every production process has precise requirements in terms of work processes, ergonomics and flexibility. The integration of automated guided vehicles in final assembly allows processes to be optimized and automated down to the smallest detail and manual operations to be efficiently combined. With a large number of our implemented systems, we can draw on extensive expertise and respond very specifically to your requirements.

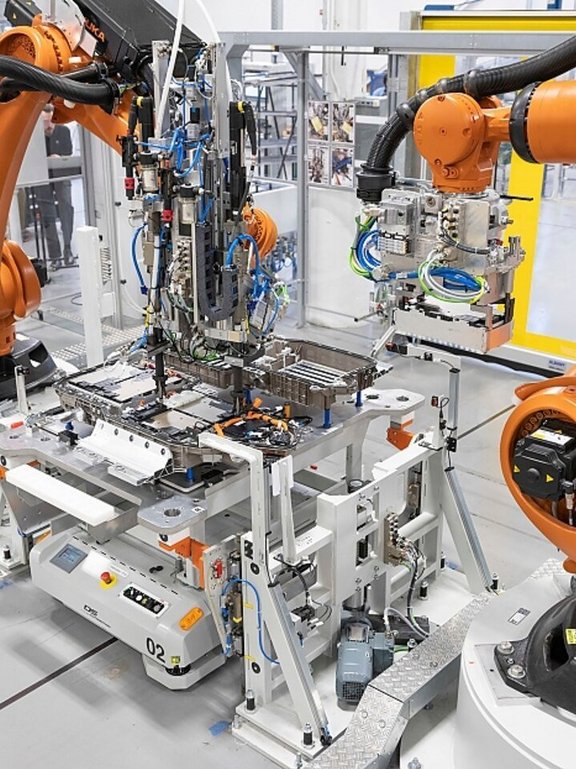

Concatenation

Many steps in production are now automated from the outset, promoting consistent quality and maximized production volume. But the individual stages of production often take place at separate locations and therefore require goods to be transported from one area to the next. Driverless transport systems come into play to save time here as well.

Technical data

Flexible vehicle for assembly lines with highest ergonomics

- Payload: max. 1,290 kg / 2,844 lbs

- Speed: up to 1 m/s / 3.3 f/s

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/8/csm_DS-Automotion_Thumbails_Fleximover-Trike_32a8822953.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/1/5/csm_DS-Automotion_Thumbails_Daimler_Bremen_edb882cf21.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/6/csm_DS-Automotion_Thumbails_Fleximover-Car-Chassimover_9519514814.png)