The fact that different electrically driven and autonomous vehicles have to get along with each other on the factory premises is a common occurrence in intralogistics today. If they are also from different manufacturers, things can get complicated. A common standard from Europe has been providing a remedy for some time now - the VDA 5050. More and more manufacturers are relying on it, and now it is to become a global standard. Wolfgang Hillinger, DS Automotion and VDA tells us how.

Interview: Peter Nestler

Share article

How did the basic problem around the relatively new VDA 5050 standard arise?

Wolfgang Hillinger: The basic problem on the subject arose with our customers. A large proportion of our customers are from the automotive industry, which belongs to the VDA (Association of German Automobile Manufacturers). They have recognized that the product and solutions of AGVs (automated guided vehicles) and AMRs (autonomous mobile robots) are becoming increasingly important to them and are an important part of their own production. They have already installed many of these systems and have found that there are many different manufacturers with different systems. This may not yet be so critical in the case of a production line, but in the field of intralogistics the issue can become noticeable, when different vehicles from different manufacturers want to use one and the same route. It can turn out that this situation, which is banal in itself, is occasionally quite difficult. Furthermore, the situation has arisen on the part of VDA that a control system is desired in a plant that can manage and control all my vehicles. Ultimately, this is a question of efficiency and reliability within a plant.

Initially, there were a few isolated solutions to this question, none of which were a great success, partly because not all manufacturers were involved. And with this initial situation, the VDA then approached the VDMA (German Engineering Federation) and said: "We have a wish - we would like to start a standardization and harmonization process where we are able to standardize fleet control and also the vehicles. We approached the VDMA because all the AGV manufacturers are represented there. That was also the starting signal for a new department to be founded in the VDMA on the subject of driverless transport systems and AMR, with the agenda of starting the automation process mentioned. The VDA 5050 standard was then launched as a result of these efforts.

Development began with the question: Who is interested in working on this? At the beginning, it took a while until we were able to arouse the interest of the companies to participate. But soon a core number of the relevant players sat around the table together and said: Yes, we want to take this step together and look at how realistic it is to pursue this goal together.

This initial situation always occurs during the development of new standards. What is the character of VDA 5050? Standards are usually recommendations.

Wolfgang Hillinger: This is a classic standard. We started with a standardization protocol: Before we wanted to go into details, we should commit to a common protocol on how we talk to each other on the systems. That was the starting point for the development of the standard - to standardize the communication level. We examined what information is distributed and already recognized how differently the individual systems work. In some cases, there are different ideologies. For some manufacturers, fleet control is only necessary so that I have an interface to the customer system, but the intelligence is entirely with the vehicle. Others assume that their system is so smart that it can handle all situations from the vehicle side. So we first had to get all the stakeholders around the table and identify the issues.

The first step was to harmonize simple systems, in this case lane-bound vehicles. There is only communication at intersections. That's how it started - with simple complexity, and then even greater complexity was introduced and mastered, up to and including the consideration of different types of navigation.

In the meantime, we have already reached a certain level where we can control different vehicles of various types - for example, a vehicle that drives under a load, which can be a forked vehicle, whether laser-navigated, contour-based, with magnetic navigation - in other words, the whole range.

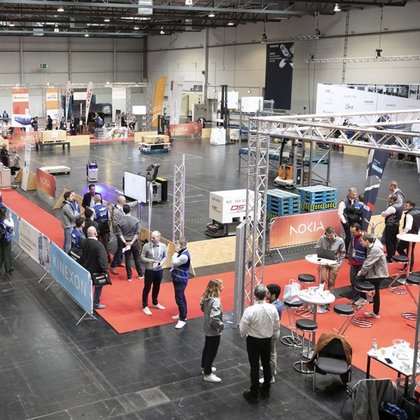

Once a year there is the IFOY Award. And we used this platform to do a so-called mesh-up. This is an event organized by the VDMA, where we hold a live event to show how far we have already come in harmonizing systems. This year, seven different manufacturers were already involved. We were given a test area and on this we jointly mapped a driving course on which a wide variety of vehicles drove at the same time. And these were controlled and managed by a common fleet control system. In this way, we want to demonstrate the complexity we are now capable of handling and thus show the state of progress continuously.

What topics and applications does VDA 5050 currently cover and what will be added? This can become very complex over time.

Wolfgang Hillinger: This will enable us to operate with a uniform fleet control system for our classic AGVs and AMRs. This will also enable us to say to our customers: You order new vehicles from me, but you also want to have three vehicles from another manufacturer in the same system. And we will then implement this together and put it into operation.

How is this fleet control handled then. Is it a uniform software or a common control system?

Wolfgang Hillinger: Each manufacturer has its own software package for controlling vehicles. And the companies that are collaborating on the development of the standard under the common VDA 5050 standard are upgrading their existing fleet control systems to take this standard into account. We have also further developed our corresponding product NAVIOS in this way and have implemented the VDA 5050 concept in its entirety. We are therefore also able to integrate an existing system with vehicles from other manufacturers. All I need to know is whether the other supplier is also VDA 5050 compliant. Essentially, we also save the discussion of earlier days about who adapts their system to which.

There was always a stalemate where no one wanted to move. And the customer realized that he wasn't really getting anywhere. In addition, it was often unclear who was actually responsible for commissioning a system. Today, it is also a matter of creating a certain role model and a responsibility matrix. And the VDA 5050 standard can ensure this. Now it is clear what a manufacturer must deliver and what the corresponding responsibility looks like. This can also be used to create a declaration of conformity. At the end of the day, we hand over the plant to the customer and then it must be ensured that everything has been implemented in accordance with the standard.

What is the current level of manufacturer participation in the VDA 5050 standard? Who is involved - or better: Who is not involved?

Wolfgang Hillinger:The major players are all involved in the development of VDA 5050. There is already pressure from the customer market on the manufacturers that are still missing to also participate. The standard means a great benefit for the customer, because he not only buys a certain flexibility, in the sense that he becomes somewhat more independent of the choice of supplier. After all, they can always mix up the systems.

On the other hand, doesn't this mean a threat to manufacturers if the customer is so free in his decisions? After all, he no longer has to take everything from a single source using the VDA 5050 standard.

Wolfgang Hillinger: At the beginning of the development of the standard, people actually saw a kind of threat and asked themselves: Where does this lead? And there were fears of loss of business. But all those who have taken a serious look at it have realized that it is also an opportunity. Because every manufacturer has different focuses and approaches in the development of its products, and therefore also different competencies within the company. In a development like this, you also have to emphasize the positive aspects, I think.

Suppliers have also realized that it can be worthwhile to sell equipment with relatively little risk, or where the risk lies elsewhere and not in their own area. And the awareness has spread among manufacturers that what others offer is not necessarily bad. Thus, the development of the standard was also positive for the market itself. In the end, a community was formed, where it was recognized among the developers that a certain spirit had emerged and that it was possible to develop cool solutions.

Are there still important manufacturers who do not participate in the VDA 5050 standard and for whom it would pay off to integrate them? How do you go about it?

The automotive industry is convinced by the concept. In a next step, we now want to create a global standard with VDA 5050. However, we are currently severely limited in the VDMA as far as cooperation is concerned. So we have said that we can only create a global standard if we also increase the number of participants in the development process, i.e. globally. Not only the manufacturers must be involved, but also the customers and other relevant stakeholders, who should be able to contribute their interests. We have now decided in the VDMA that we will form a working group. To this end, a working group is being outsourced from the VDMA. This now has the opportunity to bring on board all customers, suppliers and stakeholders from the field, universities, etc., so that they can collaborate on this further development.

The starting signal has now been given and we are already looking for stakeholders who can and want to contribute to the development. The VDMA still has the lead, but the possibilities are now different. In any case, we already said at the beginning of the development: If we want to have a global standard, then it has to be open source, because that's the only way it can be adopted and the only way our customers will see the benefits of it. We are confident about the further development of VDA 5050 into a global standard. And in October there will be a conference where we will present VDA 5050 for the first time on the North American market.